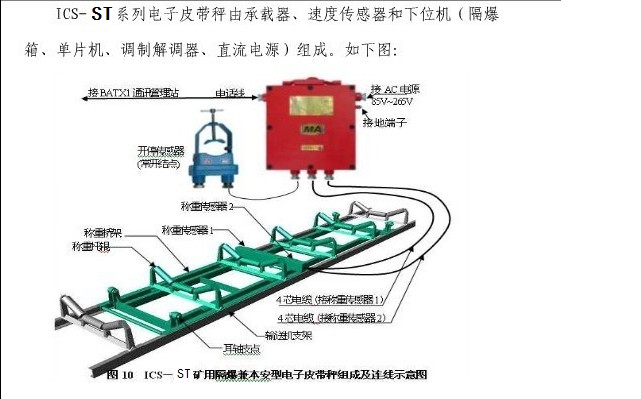

ICS-ST series mine electronic belt scale

Description:

ICS - ST mine type electronic belt scale is my company production for many years is generally based on the technology of electronic belt scale, at the same time, combined with years of coal mine explosion-proof nuclear according to the production and use of technical experience, after many years of careful technology research and development of new underground coal metering equipment, is the earliest underground local display products and electronic belt scale system MA certification of enterprises, products can adapt to bad underground industrial site, the timely and effective assessment of coal mine production metering, greatly improve workers' positivity and raw coal recovery rate, improve the production efficiency and management level of coal production enterprises.

System composition:

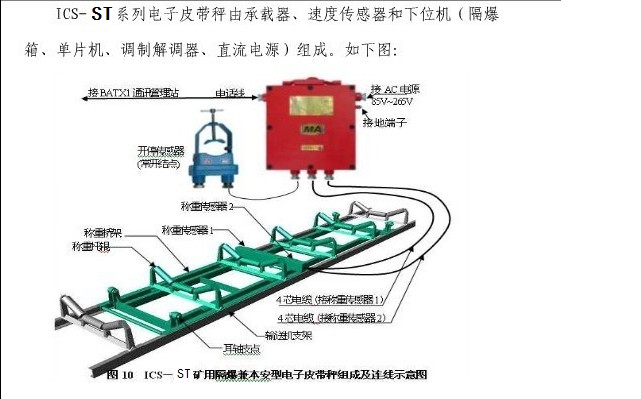

ICS-ST electronic belt scale consists of four parts:

1. Weighing bridge 1 set

2. One sanyuan weighing controller (instrument)

3. 2 weight sensors

4. One speed sensor and one speed measuring roller

Main technical parameters:

◆ under normal load, the flow rate changes within 20-100%, and the dynamic cumulative error is better than ±0.25%-1.0%.

◆ suitable for coal mine underground gas explosion dangerous environment.

◆ belt width: 500-2200mm, belt speed: 0.1-5m/s, weighing range: 10-10000t/h.

◆ the average trouble-free operation time is more than 30000 hours.

◆ working and installation conditions: power supply voltage: ac85-265v 50HZ; Ambient temperature: -20℃--+50℃.

Equipment composition:

Electronic belt scale body for mining: fully suspended or suspended standard (hanging) type rectangular steel weighing bridge: with sufficient stiffness and strength and less ash on surface area, suitable for various harsh environments such as heavy load and overload; The weighing body contains 2-4 imported high-precision alloy steel weighing sensors;

Mine speed sensor: two types of stop-start sensor and mine speed sensor.

Mine electronic belt scale digital display extension:

◆ ultra-wide power supply: AC85--265V 50HZ.

◆ flameproof and intrinsically safe, EXD[ib] can display 25 kinds of parameters such as signal, speed, flow rate, shift output and accumulative quantity in place underground, and the data is always saved and will never be lost in power failure.

◆ can be used for on-site debugging and calibration operation to solve the method of continuous contact between the well and the underground during debugging; It can also be displayed locally and independently constitute the unit of underground local display and measurement control system, and output RS485 communication interface;

◆ independent measurement: the measurement result is not affected by power failure, failure and communication line of the central station. It can automatically change shifts and store the output of 90 shifts. After the line is clear, the data will be uploaded automatically without loss.

◆ with hanging code, chain code and physical inspection functions, reduce the workload of calibration and maintenance.

◆ with automatic zero adjustment, automatic fault diagnosis, historical query, regular query function, power loss data maintenance function;

Measurement system monitoring software:

◆ multiple charts and dynamic curves showing signal voltage, output, instantaneous flow, and belt start and stop time accumulation;

◆ rich and flexible report functions, able to perform a variety of statistics, inquiries and printing of shift output, daily, monthly and annual output;

◆ with automatic zero adjustment, automatic tracking, automatic fault diagnosis and alarm, historical query, regular query function, power loss data maintenance function;

◆ the communication metering software can be equipped with 16 electronic belt scale equipment both on the well and underground, and the network metering software can be equipped with 16 electronic belt scale equipment.

◆ with the fault detection function of the metering device, when the metering device fails to meet the load exceeding limit, flow exceeding limit, speed exceeding limit and other faults, it can send an alarm signal and upload the alarm signal to the server of the central station to inform the management personnel to deal with the fault technically;

◆ with operator and engineer operation permission password, according to the permission can be the upper computer software underground permission operation, convenient management.

System features:

◆ high dynamic measurement accuracy, stable performance, reliable work, small zero drift; No change in long-term measurement accuracy; Under normal load, the flow varies from 20 to 100%, and the dynamic measurement error is better than ±0.25% to 1.0%.

◆ the average trouble-free operation time is more than 30000 hours.

◆ original mine telephone lines can be used for communication lines to reduce investment.

◆ can realize the network connection, through the Web release to achieve the local area network data sharing, facilitate the leadership to understand the production information.

◆ operators can complete the daily calibration and condition management of downhole electronic scale without going down the well;

◆ production benefit statistical analysis function, unique anti-cheating data processing function;

◆ belt scale data can also be entered into the industrial ring network switch under the mine through the RS485/RJ45 converter (IP address can be set up), the upper computer belt scale set control software through the LAN belt weighing and metering data collection, to increase the speed, stability, reliability of data collection, and to overcome the limitations of the field hardware conditions.

TEL:133-0520-1772

TEL:133-0520-1772