Product name: intelligent metering platform

With the use of advanced measurement and weighing methods in transportation and production, especially the application of information technology, the development of productivity has been greatly promoted and the enterprises have obtained obvious benefits. However, with the continuous expansion of the enterprise scale, if the enterprise still adopts the traditional data transmission method, that is, the use of telephone or documents to report step by step, the data report will not be timely and accurate, which will affect the in-depth management of the internal production of the enterprise.

In order to make enterprise management and decision-making level and production field synchronous control of various devices all production data, mining enterprises urgently need a kind of real-time data collection and management platform, fundamentally avoided due to the geographical location, communication, human factors, such as adverse effect, changing the original production data management model and improve overall efficiency of enterprises at the same time, the management and decision-making for the company to provide timely and reliable basic data.

Although there has been a great development in the application of integrator in China in recent years, there is still a big gap between China and other countries in the same industry. The research and development of special software for the industry lags behind, and the research and development force is weak; Informationization is deepened unilaterally with less comprehensive development; Information standards are not uniform, and it is difficult for enterprises to share information; The management mode is relatively backward and the information products have poor universality. Professional software function is single, comprehensive software function is not professional. There is a strong demand for information networking of weighing equipment in related industries.

To meet the above needs, xuzhou juyuan measurement and control technology co., ltd. and China united network communications co., LTD. Xuzhou branch jointly developed the intelligent metering platform. The system is based on the architecture of B/S mode product data acquisition system, and the related data are described in detail. Ability to query real-time data on a handheld device. With the popularization of Internet, 3G and the wide application of Web technology, people can even carry out production management in mobile, which will bring great convenience to enterprises.

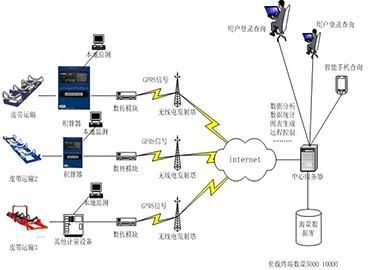

The system structure

The weighing data is transmitted to a central server via a transfer module installed on the weighing device. The weighing data processing and calculation are completed by the central server, which can load 5,000-10,000 transmission modules at the same time. Users can use web pages and mobile phones of B/S framework as data monitoring terminals for real-time access to the data server and historical query, and the measurement statistics can realize real-time monitoring of measurement data.

System functions and features

Automatic remote wireless acquisition of integrator weighing data

Report statistics and intelligent analysis

Real-time monitoring of each integrator output (annual, monthly, daily, shift output summary and single weight)

User permission setting and security functions (hierarchical permission setting)

Support Web query function; Support 3G mobile phone real-time online query, multiple metering equipment management

Historical records can be viewed. Historical records can be kept for 5-10 years, depending on the database storage

You can view the state of the integrator at any time

Data analysis and statistics; Make intuitive statistics on the integrator (annual, monthly, daily and shift output)

Alarm upper and lower limits can be set on the integrator

Perfect shift setting function

Perfect user cross - management function

The main characteristic of this system is the coverage scope is large, can be installed in the GSM network coverage scope; Large system capacity; Small investment, short project cycle, simple maintenance, no need to establish a special communication network; Fast data transmission speed and high reliability; The volume of the terminal device of the integrator is small, which is convenient for hidden installation. Data transmission by reliable encryption, to ensure the system communication security; Good scalability.

1. Low-cost investment in network construction

This system relies on the mature GSM public network system, so it does not need a separate network (base station and other equipment). And do not need to invest in the daily transmission network equipment maintenance funds.

2. Wide application

Domestic power, coal, metallurgy, mining, port, chemical industry, building materials and other industries of bulk material measurement system are potential customers, the corresponding measurement system can be modular upgrade service; The application scope and application objects of the platform are very wide.

3, the structure of building blocks, simple and convenient, strong applicability

This system supports multi-stage multi-center structure with different size of building blocks, which is suitable for all kinds of different units and all levels of management departments, so as to implement real-time tracking management of all kinds of different properties. Its cost is low, easy to popularize, scale can be big or small, and need not have the trivia such as high-speed data special line and equipment.

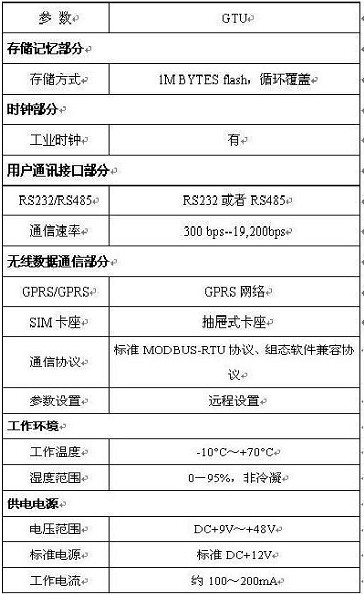

Performance indicators: software interface:

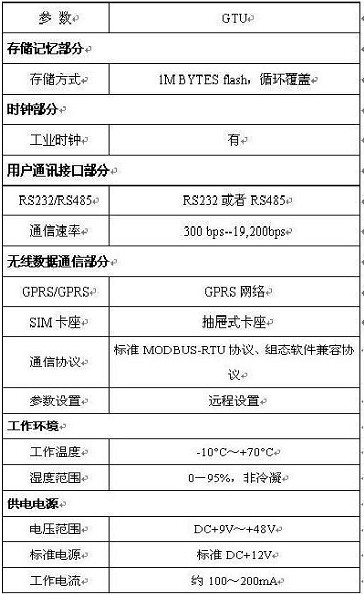

The terminal equipment of the integrator is developed and produced by xuzhou juyuan measurement and control technology co., LTD. Performance indicators are as follows:

TEL:133-0520-1772

TEL:133-0520-1772